Perspectives on broiler starter feed in China, after one year without AGPs

Eugene Li, Nutritionist, Hamlet Protein

Antibiotics at therapeutic dosages prevent and treat intestinal diseases in modern broiler industry, whereas antibiotic growth promoters (AGPs), at sub-therapeutic doses in feed, can improve growth performance and gut health of broilers.

Since July 1, 2020, when the Chinese government banned AGPs in feed, it has become critical to maintain broiler performance and improve feed conversion rates, especially with the implementation of multi-dimensional caging rearing systems in North China, which results in increased bird density. Other challenges have been the high level of toxins and anti-nutritional factors (ANF) in feed ingredients, causing serious intestinal health problems in chickens. It has now been a year since the Chinese government's ban of AGPs. What is the status of broiler feed formulation in China after this year?

Precise nutrition application to ensure enough nutrients intake

It is essential that nutrients meet broiler growth requirements. Particularly for young chicks, the starter diet must be formulated accurately to ensure that the energy, amino acids, vitamins and trace elements meet the basic nutritional requirements for the development of digestive tract, endogenous enzyme secretion and immune system maturation. In this sense, low protein diets are not accepted in China yet because rapid growth is still the first priority for young broilers. Thus, standard ileal digestibility (SID) is widely used in broiler feed formulation. The recommended amino acids in broiler diet are in average SID Lys 1.28, SID Met 0.51, SID Thr 0.97, SID Trp 0.20, etc.

Strict quality control of feed ingredients

An accurate assessment of feed ingredients, such as energy utilization rate and amino acid digestibility, is a prerequisite for making precise broiler feed formula and subsequently improves feed conversion efficiency. The right selection of ingredients influences feed costs and determines the quality of the products. For cereals and their processed by-products, besides considering the nutrient digestibility, a strict detection of mold and mycotoxins needs to be implemented to minimize the potential harm of mycotoxins to broilers. In order to eliminate the effects of anti-nutritional factors (ANFs) on nutrient absorption and gut development of chicks, soybean meal is usually extruded, fermented or enzyme treated. The intestinal problems caused by ANFs in broilers could be controlled by AGPs. After AGPs were banned, broiler feed mills are using protein ingredients with low ANFs, such as HP AviStart from Hamlet Protein, to prevent intestinal inflammation and oxidative stress.

Enhance the vitality of young chicks

Day-old broiler quality is influenced and determined by genetics and hatching conditions. However, early nutrition is also crucial and even the embryo quality can be enhanced by improving the breeders’ nutrition. Numerous Chinese broiler integrators are adding more synthetic amino acids, such as threonine in the breeder diet to improve the survival rate of their offspring. Another tool is the supplementation of vitamin E, which can increase the daily gain, survival rate and Newcastle disease antibody titer of broiler offspring.

Strengthen nutrition for newborn chicks

Adding extra exogenous enzymes, prebiotics and probiotics in newborn chicks’ feed can improve gut health and nutrient utilization. Butyric acid is being added in starter diets to maintain the microbial balance in the intestines. Phytase superdosage has become a common application because it increases protein digestibility and releases more available phosphorus from the chick diet. In the same way, the addition of non-starch polysaccharide (NSP) enzymes improving the digestibility of NSP, is improving the intestinal health of poultry and provide additional energy.

Control Clostridium perfringens, coccidiosis and necrotic enteritis

Clostridium and coccidia are the most common pathogenic microorganisms that threaten the intestinal health of broiler chicks. Furthermore, coccidian oocyst and clostridium can be widely found in soil and water anywhere. When coccidia oocysts and Clostridium cells are proliferated quickly in gut, it will challenge poultry health, reducing production efficiency and probably increase mortality. Necrotic enteritis due to Clostridium perfringens, may be caused by poor diet compositions, immunosuppression and oxidative stress status, intestinal physiological pathologies and coccidiosis, which damage gut integrity. In this sense, coccidiosis vaccines have been used to control coccidiosis in yellow-feathered broilers raised on floor rearing systems in southern China in order to strengthen the control of intestinal health to reduce the occurrence of necrotic enteritis. Intestinal health can be improved when enzyme-treated soy protein is added to broiler starter feed, significantly improving the performance of clostridia-and Clostridum-challenged chicks.

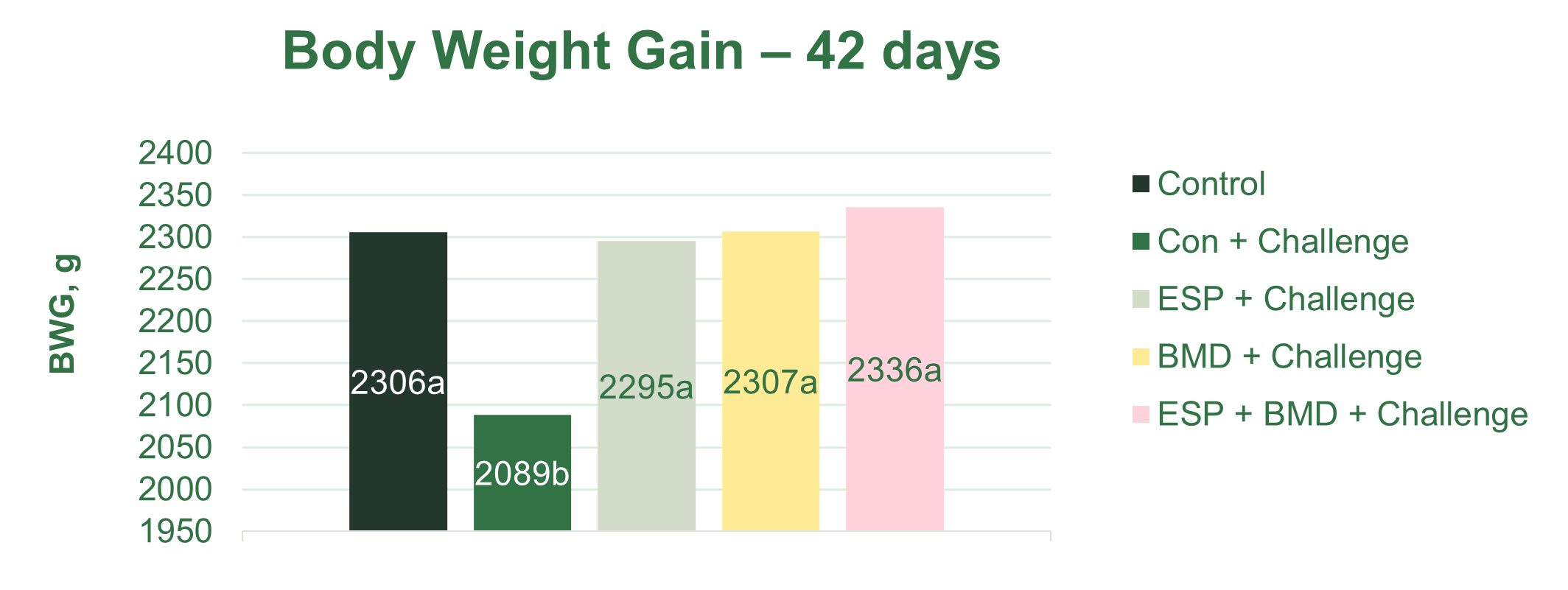

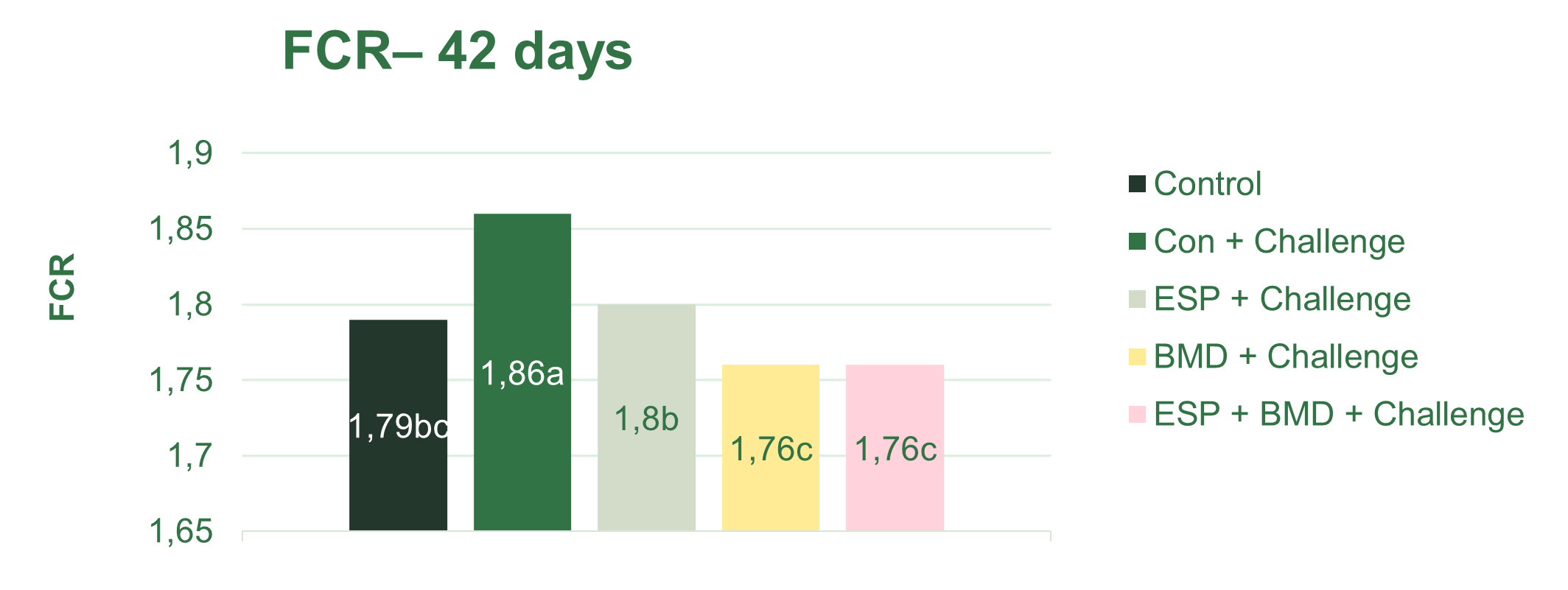

Rasmussen et al. (2019) reported that the addition of enzyme treated soy-protein (ESP) in starter diets, with or without AGPs throughout the broiler production cycle, equals the weight of birds vaccinated against coccidiosis and infected with Clostridium perfringens and their FCR to that of uninfected chickens (Figure 1 and 2).

To sum up, after AGPs were banned in China, broiler feed mills and integrators have been using a variety of nutrition solutions to ensure chicks’ health and performance including precise nutrition, strict ingredient quality control and more specifically the selection of high-quality protein sources for starter feed.

Figure 1. Effect of enzyme-treated soy protein (ESP) on body weight gain of coccidiosis-vaccinated and Clostridium-infected chickens on day 42.

Figure 2. Effect of enzyme-treated soy protein (ESP) on FCR of coccidiosis-vaccinated and Clostridium-infected chickens on day 42.

Events with Hamlet Protein

We attend events around the world. Meet us at exhibitions and seminars - we always look forward to welcoming you!

We also sponsor conferences with focus on young animal nutrition.

Have a look below where to meet us next.